|

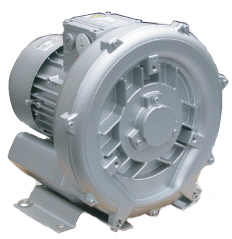

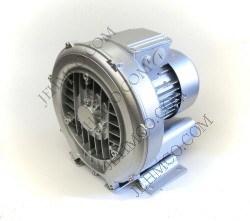

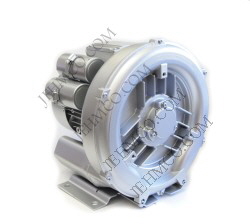

Blowers are the next alternative when our largest Linear Piston Air Pumps

or Diaphragm Pumps will not suffice with adequate air volume for larger Fish Rooms. The smallest blower we now carry is a .29 HP unit which can handle upwards of 100 outlets in moderately deep tanks. Blowers smaller than this do not have adequate pressure to supply air to deep tanks and in most cases our Linear Piston Air Pumps will outperform the smallest blowers (such as 1/8 HP). Since a piston has a fixed volume of air capacity due to the physical size of the cylinder and the maximum strokes per minute possible, there comes a point where large air requirements can not be met economically with the piston design (purchase cost of multiple piston units. Although Linear Piston Pumps have better pressure ratings than small Blowers, their output does not fall off as sharply as pressure increases over 1 PSI. Air distribution systems can be designed using 3/4” or 1” PVC pipe with the Linear Piston Pump. Regenerative Blowers are more like wind machines with the ability to attain moderate pressures (due to the “regenerative” action of impeller/housing design) on the mid to larger sized units (1/3 HP+) and will produce extremely large volumes of air with the appropriate distribution system design. Note that even minimal restrictions in piping, air valves, airstones (if used) and dirty or undersized intake filter all will contribute to added back pressure on any air source. Therefore,

water depth alone is not the only criteria that should be considered when selecting the correct Blower / Air pump. Minimum pipe size we recommend for smaller Blowers is 1 1/4” PVC with as few and gradual

(shallow radius) turns where possible and utilizing a looped pipe system.

If a Blower is not being used to capacity, excess air should be “bled off”. Opening a large valve until desired flow is achieved is usually adequate, but more precise control and best efficiencies are

obtained if a meter or a sensitive low pressure gauge is used to check lowest current draw or correct air pressure. Use our Bleed Exhaust Diffusers to reduce noise and control amount of air to bleed.

Better quality Blowers will provide good pressures while maintaining design flow rates. Good impeller and housing design provide lower noise levels than lesser grade machines. Superior

motor construction will provide for longest life expectancy (MTBF). These are some of the criteria we used when deciding on our Blower line. As in all of our products we feel that buying quality pays off with “less aggravation, less maintenance and higher efficiencies”.

|

0.29 HP Blower:

0.29 HP Blower:

0.4 HP Blower:

0.4 HP Blower:  5/8 HP Blower:

5/8 HP Blower:

0.8 HP Blower:

0.8 HP Blower:  1.1 HP Blower:

1.1 HP Blower:  1.27 HP Blower:

1.27 HP Blower:  2 HP Blower:

2 HP Blower: 2.35 HP Blower

2.35 HP Blower